Drive-by-wire technology rewires the vehicle's functions

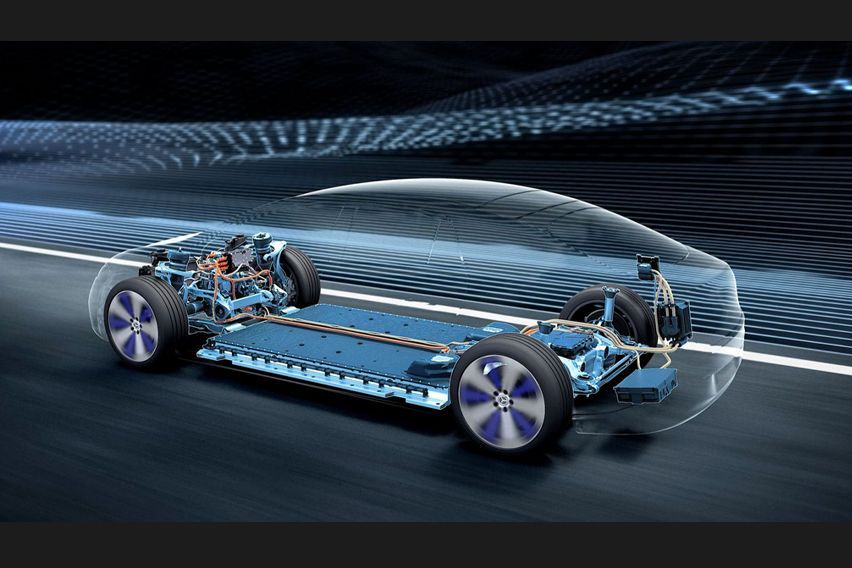

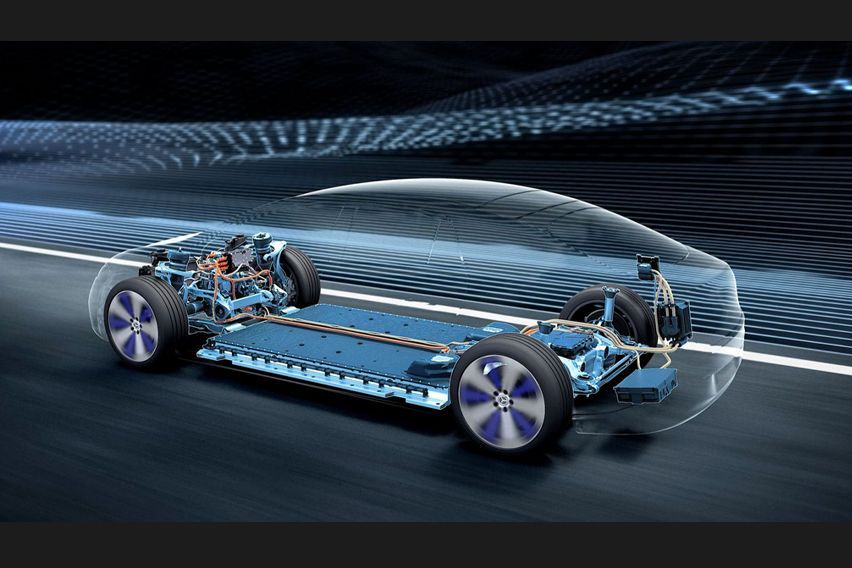

You may have heard the comment that cars have become computers on wheels. And in a way, that's true: Mechanical components of many modern cars have been replaced by electronic systems.

KEY TAKEAWAYS

How does drive-by-wire technology work?

Drive-by-wire technology employs electronic systems to trigger brakes, control steering, and fuel the engine in place of cables or hydraulic pressure.Are there vehicles that use full drive-by-wire technologies?

Although there aren't any entirely drive-by-wire production cars yet, tractors and forklifts use drive-by-wire technology and even vehicles with electronic power steering still have physical steering linkages.A broad term used to describe a variety of electronic systems that either supplement or replace conventional mechanical controls is "drive-by-wire." Drive-by-wire technology employs electronic systems to trigger brakes, control steering, and fuel the engine in place of cables or hydraulic pressure.

Throttle, brakes, and steering are the three primary driving components that drive-by-wire systems commonly replace with electronic controls. Electronic throttle control, brake-by-wire, and steer-by-wire are the common names for these systems.

Electronic throttle control

Electronic throttle control is the drive-by-wire technology that is most widely used and most accessible. These systems employ a number of electronic sensors and actuators, as opposed to conventional throttle controls that connect the gas pedal and throttle with a mechanical cable.

Throttle sensors have been utilized for many years in vehicles with computerized fuel controls. The throttle is still operated by a physical connection even if these sensors inform the computer of its location.

True electronic throttle control (ETC) vehicles lack a physical link between the accelerator and the throttle. Instead, the throttle is opened by an electromechanical actuator thanks to a signal the gas pedal transmits.

Since it is simple to use and has a fail-safe, foolproof design, this form of drive-by-wire technology is frequently regarded as the safest. Electronic throttle control systems can be created so that the throttle closes if it's no longer receiving a signal from the pedal sensor, similar to how a mechanical throttle cable would if it were to break.

Brake-by-wire

Some believe that electronic throttle control is less risky than brake-by-wire technology because it does not physically connect the driver to the brakes.

However, there are a variety of brake-by-wire technologies, including electro-hydraulic and electromechanical systems, both of which can be built with fail-safes in mind.

A master cylinder and many slave cylinders are used in conventional hydraulic brake systems. The master cylinder experiences physical pressure when the driver depresses the brake pedal.

The majority of the time, a vacuum or hydraulic brake booster increases that pressure. The pressure is then transferred to the brake calipers or wheel cylinders through brake lines.

Anti-lock braking systems were the early versions of brake-by-wire technologies, since they made it possible for a car's brakes to be applied automatically and without a driver's involvement. An electrical actuator that engages the existing hydraulic brakes makes this possible.

On top of this basis, several safety technologies have been developed. Brake-by-wire technology is related to electronic stability control, traction control, and automatic braking systems, which all rely on ABS.

Steer-by-wire

The steering wheel is physically attached to the majority of automobiles' rack-and-pinion steering units or worm-and-sector steering gears. The steering box or rack-and-pinion unit also rotates when the steering wheel does. The steering linkage is normally moved by a steering box using a pitman's arm, and a rack-and-pinion unit can then apply torque to the ball joints through tie rods.

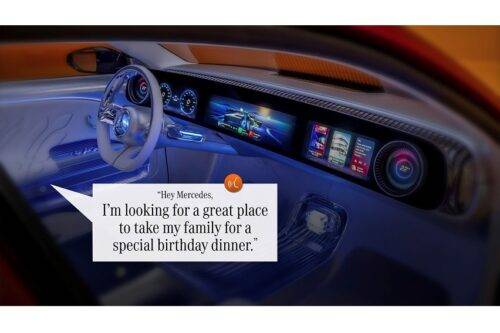

There is no physical connection between the steering wheel and the tires in cars using steer-by-wire technology. Technically speaking, steering wheel is not even necessary for steer-by-wire systems. In order to give the driver sensation when using a steering wheel, several steering feel emulators are frequently employed.

Vehicles with drive-by-wire technology

Although there aren't any entirely drive-by-wire production cars yet, several carmakers have created concept cars that fit the category, as do construction vehicle makers.

Tractors and forklifts use drive-by-wire technology, but even vehicles with electronic power steering still have physical steering linkages.

More vehicles now use electronic throttle control, and there are many different makes and models that do so. Production models can also be found with brake-by-wire. Toyota's Electronic Controlled Brake and Mercedes-Benz's Sensotronic are said to be two examples of the technology.

Autonomous vehicles, which enable remote operation or through a computer, might also be combined with drive-by-wire. The technology is connected directly to the electromechanical actuators that control the self-driving car's steering, braking, and acceleration.

Drive-by-wire technology is, well, rewiring the progress of the automobile.

Photos from Mercedes-Benz and Roy Robles

Sell your car at the best price

Verified and genuine buyers

Verified and genuine buyers

Trending & Fresh Updates

- Latest

- Popular

You might also be interested in

- News

- Featured Stories

Featured Cars

- Latest

- Upcoming

- Popular

Latest Car Videos on Zigwheels

Car Articles From Carmudi

- journal

- advice

- financing

- insurance