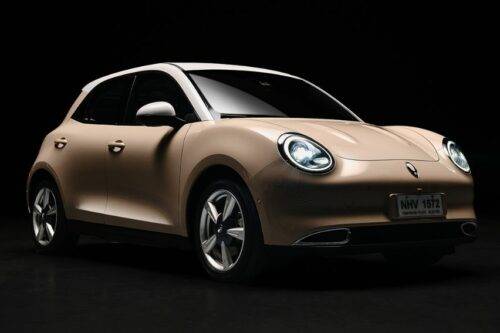

Audi to launch all-electric vehicles only starting 2026

MANILA: Starting in 2026, Audi will only release all-electric vehicles onto the global market, gradually ceasing combustion-engine models by 2033. Audi has taken a clear commitment to produce all-electric vehicles, and as part of its Vorsprung 2030 corporate strategy, it is now putting its global facilities in place for this goal.

KEY TAKEAWAYS

What is Audi's goal in terms of production costs?

Audi plans to cut yearly plant costs in half by 2033 to ensure future production will be cost-effective.What is Audi's target in terms of the environmental impact of its production process?

By 2030, Audi aims to reduce its absolute environmental impact in the areas of primary energy consumption, power plant emissions, CO2 equivalents, air pollutants, local water risk, and wastewater and waste volumes in half, compared with the 2018 figure.Audi is expanding on its current global production network to fulfill this ambition. “Step by step, we are bringing all our sites into the future. We don’t want any standalone lighthouse projects on greenfield sites. Instead, we are investing in our existing plants so they end up being just as efficient and flexible as newly built production sites or greenfield plants,” Audi Board Member for Production and Logistics Gerd Walker stated. He claimed that this exemplifies sustainability in its social, ecological, and economic facets. “The path Audi is taking conserves resources and accelerates our transformation to a provider of sustainable premium mobility,” Walker said.

Walker wants production to be adaptable and resilient in order to make it future-proof. Audi created an entire strategy with this objective in mind, taking different perspectives into consideration, including the expectations from the society, the demands of the customers, the expectations of stakeholders, and the needs of the employees. In response, Audi developed a futuristic concept, the 360factory. The approach puts equal focus on cost-effectiveness, sustainability, versatility, and appeal.

All of Audi's manufacturing facilities around the world will be producing electric-drive models by the end of the decade. “To achieve our goal, we are relying on our highly qualified staff and will make all our employees fit for the future by 2025 with a training budget of around €500 million,” Walker stated.

Two sites, Bollinger Hofe and Brussels, already produce electric vehicles. The Audi Q6 e-tron will be the first all-electric vehicle to leave Ingolstadt's assembly line next year. Moreover, Neckarsulm, San Jose Chiapa, and Gyr will all gradually begin to produce all-electric vehicles. All manufacturing facilities will be producing at least one all-electric vehicle model by 2029. Production of the remaining combustion models will gradually end by the start of the next decade, depending on regional conditions.

Only in situations where more capacity is required will new plants be constructed. For instance, a facility in Changchun, China, is being built by Audi and its partner FAW to manufacture vehicles based on the PPE (Premium Platform Electric) technology platform. This will be the first automotive plant in China to only produce all-electric Audi vehicles once construction is completed by the end of 2024.

However, electrifying its facilities is just one step in Audi's vision for the future of production. “We will use the transition to e-mobility to make major leaps in productivity and optimization by making the necessary modifications,” Walker said.

Audi's production network is designed to be efficient, sustainable, and appealing in addition to being flexible. Audi plans to cut yearly plant costs in half by 2033 to ensure future production will be cost-effective. To do this, Audi plans to apply a streamlined production process for vehicle development. Audi will also continue digitizing production, for instance, with the Edge Cloud 4 Production solution using local servers. As a result, costly industrial PCs will be replaced, reducing IT efforts like software rollouts and operating system upgrades. Cycle-independent modular assembly will be used by Audi in the future to streamline operations with significant product variability. Virtual assembly planning reduces the need for tangible resources and enables innovative, flexible collaboration.

Audi will make its manufacturing procedures even more adaptable to guarantee that it will be able to respond more quickly to changes in customer demand or production plans. “We want to structure both product and production so we get the optimum benefit for our customers,” Walker said. As an example, the new Audi Q6 e-tron will initially be produced in Ingolstadt on the same line as the Audi A4 and Audi A5. The combustion cars on the lines will then gradually be replaced by the electric models.

Audi has been working to lower its production and logistics-related ecological footprint since 2019 through its Mission: Zero environmental program. The main objective of the program is to make all Audi manufacturing facilities net carbon neutral by 2025. The factories in Gyr, Brussels, and the Bollinger Hofe in Neckarsulm have previously undergone renovations to this purpose. In addition to protecting and preserving biodiversity, the environmental program also covers resource and water efficiency. Audi targets to cut its production sites' current ecologically weighted water consumption value in half by 2035.

Photos from Audi

Sell your car at the best price

Verified and genuine buyers

Verified and genuine buyers

Audi Car Models

PIMS 2024

- Latest

- Popular

You might also be interested in

- News

- Featured Stories

- Latest

- Popular

Latest Audi Car Videos on Zigwheels

Audi Car Articles From Carmudi

- journal