By 2020, Nissan cars will be built by robots – at least, in Tochigi factory

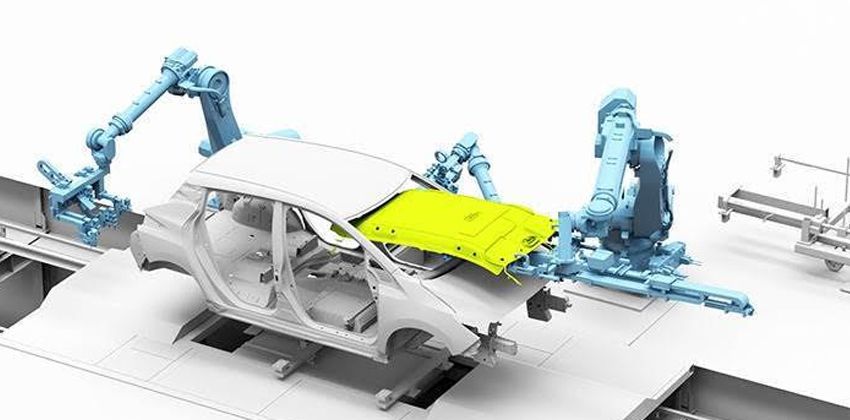

MANILA: In a bid to produce smart, electrified vehicles more efficiently, Nissan Motor Corporation is rolling out an automated production system. The carmaker will start with their flagship plant at Tochigi Prefecture where they’ll invest 33 billion yen. Once the rollout is complete,

it will be Nissan’s first “intelligent” factory.

The multi-billion investment will equip the plant with robotics, sensors, and other automated technologies. These changes are designed to optimize the production of hybrid cars and electric-powered vehicles.

Nissan announced the news last Thursday during a press conference at their Yokohama headquarters. The move to automate car production is in line with the company’s vision of Intelligent Mobility.

“We’re facing an unprecedented evolution in the capabilities of our vehicles. Our job is to make this evolution a reality by rethinking how we build cars,” Hideyuki Sakamoto, Executive Vice President of Nissan, explained.

The Japanese carmaker will introduce a “universal powertrain mounting system” to their Tochigi factory. It incorporates a robotic pallet which is capable of installing multiple car parts in a single operation.

The system can be configured with up to 27 different powertrain modules. Since it is adaptable, the pallet can be used to mount electronic ePower engines on hybrids such as the Altima, as well as standard fuel engines on regular models like the Nissan Almera.

The machine also replicates the craftsmanship of workers using simulated data. Robots can now apply finishing sealant with the exact same precision as trained professionals – if not, better.

However, workers need not be afraid of losing their jobs to these robots. Nissan said that automation reduces the physical stress of assembly-line workers. It also allows the company to accommodate a more diverse workforce which includes women and the elderly, now that work is made easier.

In retrospect, car production methods have remained unchanged since the beginning of the automotive industry in the early 1900s. With cars becoming more complex, production lines are unable to keep up.

“Manufacturing methods must change because vehicles increasingly have both hybrid and electric engines and new parts for connectivity and artificial intelligence services,” Sakamoto added.

The production changes at Tochigi plant will be completed by next year. Afterwards, Nissan will continue to roll out their automated system across factories in Japan, and then globally.

Also Read:- Check out the 50th Anniversary special edition of Nissan GT-R

Sell your car at the best price

Verified and genuine buyers

Verified and genuine buyers

Nissan Car Models

PIMS 2024

Trending & Fresh Updates

- Latest

- Popular

You might also be interested in

- News

- Featured Stories

Nissan Featured Cars

- Latest

- Upcoming

- Popular

Latest Nissan Car Videos on Zigwheels

Nissan Car Articles From Carmudi

- journal

- insurance