Nissan’s new tech to give discontinued models another life

MANILA: Those who still have Nissan vehicles in their stable, this would definitely come as good news.

The Japanese carmaker has developed a technology that gives your vehicles- even those discontinued - another shot of life as replacement parts could be developed by Nissan robots.

Nissan breakthrough technology, known as dual-sided dieless forming, is eyed to produce replacement parts for discontinued models, making it more widely available for customers.

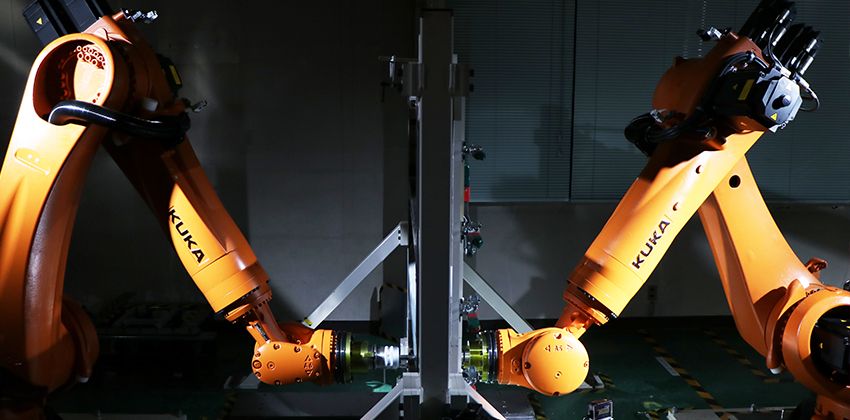

Nissan's dual-sided dieless forming involves two synchronized robots working from opposite sides of a steel sheet, using diamond-coated tools to shape the steel gradually.

Well, should do this be commercialized? It could mean cheaper parts due to better availability, as the robots are expected to yield flexible production, short lead times, and minimal upfront costs.

If you have to ask: why only now? Here is there answer:

Production of replacement parts was previously not possible due to the high upfront costs and long lead times to develop and make dies for stamped parts.

“Until now, dual-sided dieless forming had been considered too difficult to commercialize. This was due to the complexity of programming two robots to operate synchronously while ensuring consistent quality. Existing techniques have primarily relied on single-sided forming, which limits the complexity of shapes that can be created. By placing robots and tools on opposite sides of a steel sheet, they can create more difficult and detailed shapes,” Nissan stated.

Created by Nissan’s Production Engineering Research and Development Center, along with advancements in materials technology by Nissan’s Research Division, the technique represents three major breakthroughs:

- The development of advanced programs capable of controlling both robots with a high degree of dimensional accuracy, enabling the formation of detailed convex and concave shapes

- The application of a mirrored diamond coating to tools reduces friction while eliminating the need for lubrication. This has numerous benefits, including consistency of surface quality and low-cost, it is an environmentally friendly operation

- The generation of optimized pathfinding logic for robots, drawing on the ample expertise and press-forming simulation techniques ordinarily used by Nissan’s production engineering teams. This enabled Nissan to achieve high-quality results early in the development process

Further, Nissan is mulling to pursue “advancements in mass production while also dedicating R&D resources to honing its flexible low-volume production techniques.”

Also Read:- Nissan will visit you to replace your car’s Takata airbags

Sell your car at the best price

Verified and genuine buyers

Verified and genuine buyers

Nissan Car Models

PIMS 2024

Trending & Fresh Updates

- Latest

- Popular

You might also be interested in

- News

- Featured Stories

Nissan Featured Cars

- Latest

- Upcoming

- Popular

Latest Nissan Car Videos on Zigwheels

Nissan Car Articles From Carmudi

- journal

- insurance