Porsche studies use of DAC technology in eFuel production

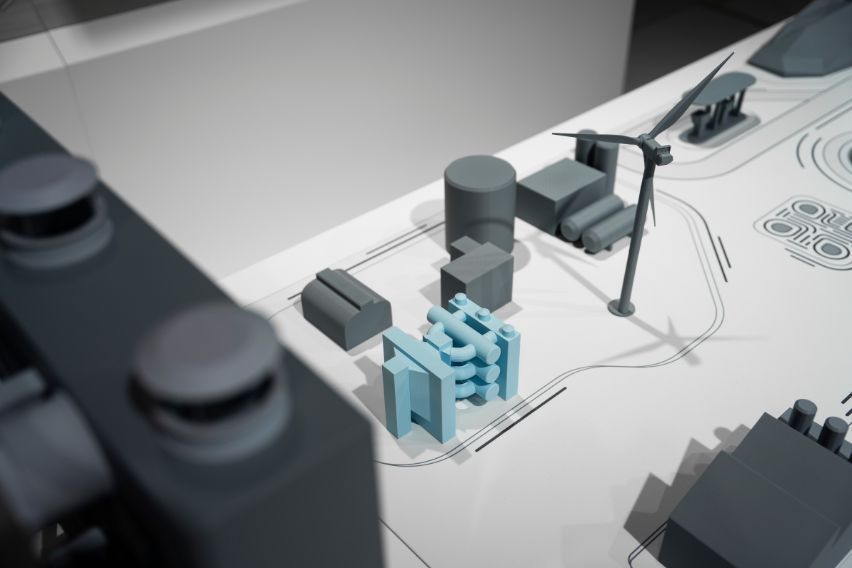

MANILA: During the IAA Summit held in Munich Germany, Porsche presented its plans of integrating a direct air capture (DAC) facility into HIF Global’s eFuels pilot plant in Chile.

KEY TAKEAWAYS

What is the key benefit of DAC technology?

One of the key benefits of DAC technology is the ability to gather CO2 anywhere there is access to renewable energy.Where can the extracted CO2 be used aside from utilizing it in eFuel production?

The extracted CO2 could also be used as a raw material in the production of non-fossil-based plastics in the future.Porsche sees DAC as an innovative new technology that is just entering mass production. By effectively and sustainably removing large amounts of carbon dioxide (CO2) from the atmosphere, DAC can make a significant contribution to the fight against global warming.

The Stuttgart-based car manufacturer plans to establish the DAC facility in collaboration with Volkswagen Group Innovation and MAN Energy Solutions. The facility could potentially be used for obtaining the CO2 needed for the eFuels production at the Haru Oni pilot plant.

“In our view, DAC is an important new technology for the future – for energy extraction and particularly for the climate. Pure CO2 can be used for industrial processes or permanently stored in the ground. It can also be used to produce eFuels – which we are planning to do as a first step. These eFuels are a useful complement to e-mobility, as there will still be many internal combustion engine (ICE) vehicles on the road around the world for decades to come,” Porsche Executive Board Member for Procurement Barbara Frenkel stated.

One of the key benefits of DAC technology is the ability to gather CO2 anywhere there is access to renewable energy. The electricity needed for the filtration system at the Haru Oni eFuels pilot plant is produced using wind energy, which is a renewable source. The required heat could be provided through the eFuel plant’s hydrogen generation process.

To extract CO2 from the atmosphere, the ambient air must first be cleared of large dirt particles before being directed through a pebble-like filter material. The generated CO2 is collected in a highly purified form for later use as a raw material.

The extracted CO2 can be utilized in many different ways. It could be used as a raw material in the production of non-fossil-based plastics in the future. It can also be used to produce eFuels, which are fully synthetic fuels. Porsche and HIF Global are looking into how DAC-extracted CO2 can be used at the Haru Oni eFuels plant where CO2 is mixed with hydrogen to produce methanol. Haru Oni currently gets its CO2 from a biogenic source.

HIF Global established its eFuels pilot plant in December 2022 to produce synthetic fuels for an almost carbon-neutral operation of ICE vehicles. In the plant’s pilot phase, the company targets to produce up to 130,000 liters of eFuel per year, which will be used in the Porsche Mobil 1 Supercup and at Porsche Experience Centers.

“We have proven that carbon-neutral eFuels can be a real solution for decarbonizing the transport sector. In pioneering SAC technology that enables efficient and low-cost CO2 capture, we are taking things a step further. We are delighted to be working with Porsche to operate this technology – the future of CO2 recycling – in the future at our plant in Chile and, in this way, make an active and timely contribution to fighting climate change,” HIF Global President and Chief Executive Officer Cesar Norton said.

Photos from Porsche

Also read:

Porsche global sales up by 18% in Q1 of 2023

Porsche adopts state-of-the-art test methods for high-voltage EV batteries

Porsche sets financial records in 2022, launches ‘Road to 20’ program

Sell your car at the best price

Verified and genuine buyers

Verified and genuine buyers

Porsche Car Models

PIMS 2024

- Latest

- Popular

You might also be interested in

- News

- Featured Stories

- Latest

- Popular

Latest Porsche Car Videos on Zigwheels

Porsche Car Articles From Carmudi

- journal