Tesla Model 3 to go Cobalt free with CATL batteries

MANILA: US giant automaker Tesla has switched to new electric vehicle battery technology that will involve a combination of dry cell and supercapacitor technology, sources in China have revealed.

The combination of these two technologies would have the potential to increase energy density, and hence driving range, as well as increase charging speed.

Reportedly, Tesla is in advanced stages of discussion to use batteries from Contemporary Amperex Technology Co Ltd (CATL), a Chinese battery manufacturer and had recently signed a deal with it for battery supplies, for over a year. LFP batteries are cheaper to manufacture than existing nickel-cobalt-aluminium batteries, by a double-digit percentage. The move will see the automaker use a new lithium iron phosphate (LFP) batteries which contains no cobalt, a metal that is considered to be one of the most expensive material in electric vehicle batteries.

It is the first time ever, that Tesla models made at its China plant will incorporate LFP batteries with an aim to lower down production costs amidst breaking sales of EV vehicles in China.

All lithium-ion cell chemistries are gaining steady improvements in energy density and benefiting from reductions in cost. But on the downside of LFP cells is its lower energy density, but to combat this, CATL is developing its cell-to-pack technology, which allows the cells to be directly integrated into packs without using modules. This saves space, with typically the same operating range.

When Tesla acquired battery tech developer Maxwell Technologies in 2019, a document released in May 2019 noted that Maxwell’s dry battery electrode technology used to manufacture its ultracapacitors “could be a ground breaking technology for lithium-ion batteries, particularly in the electric vehicle market”.

According to some reliable Chinese sources “The new battery independently developed by Tesla is a combination of dry battery technology and supercapacitor. The specific composition is expected to be explained at the Tesla Battery Conference in April.” This breakthrough could put Tesla already 6 years ahead of other electric vehicle makers with its version 3 hardware, putting it even further ahead of its game.

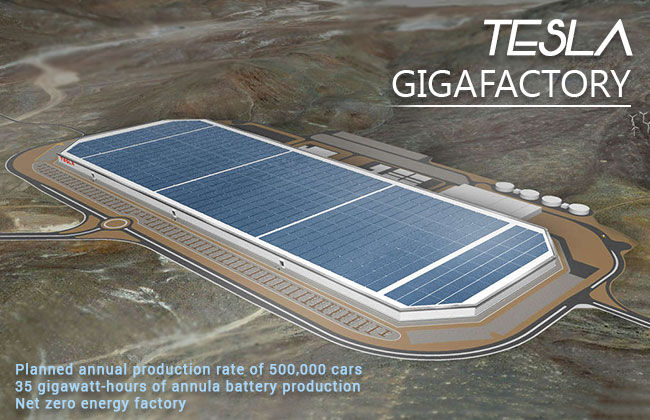

Tesla has already rolled up its sleeves to enhance production capacity of its Model 3 cars at its newly built $2 billion Shanghai plant and is aiming to lower down production costs to win market share from giant luxury automakers like Germany’s BMW.

Sell your car at the best price

Verified and genuine buyers

Verified and genuine buyers

PIMS 2024

- Latest

- Popular

You might also be interested in

- News

- Featured Stories

- Latest

- Upcoming

- Popular

Latest Car Videos on Zigwheels

Car Articles From Carmudi

- journal

- advice

- financing

- insurance