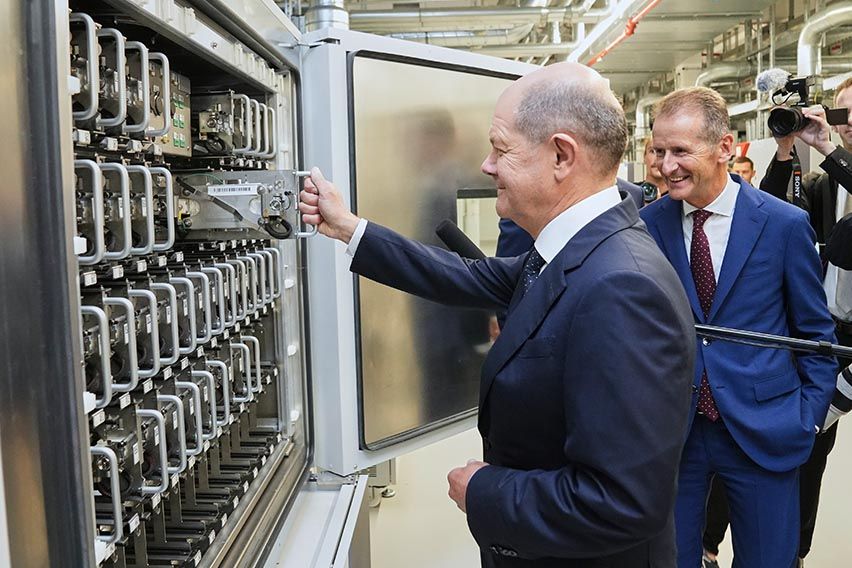

Volkswagen Group breaks ground on first cell factory in Salzgitter

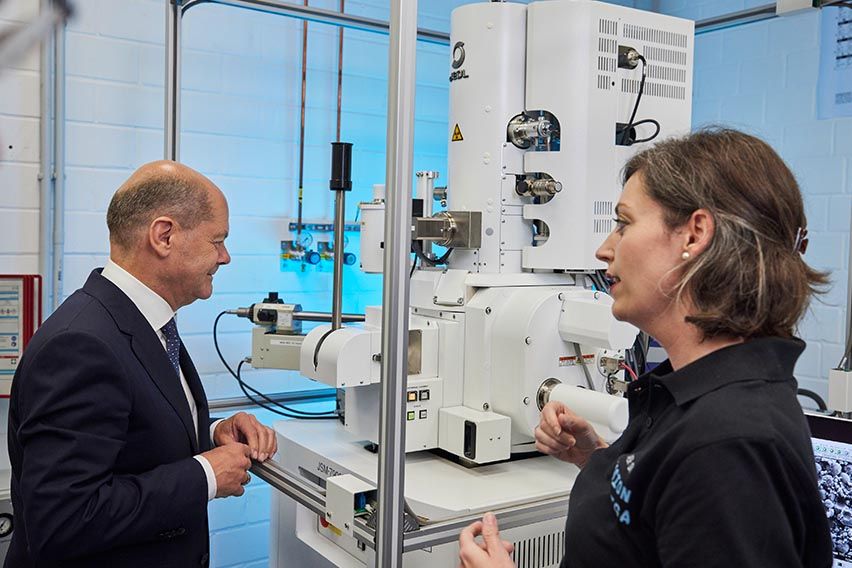

MANILA: The Volkswagen Group officially broke ground on its first cell factory in Salzgitter, Germany in the presence of German Chancellor Olaf Scholz. Production is set to begin in 2025. The newly formed company PowerCo will be in charge of the global battery business. The new company will also be responsible for all operations along the entire battery value chain. PowerCo targets to invest more than €20 billion in the business area alongside partners, employ up to 20,000 people in Europe alone by 2030, and produce annual sales in excess of €20 billion.

KEY TAKEAWAYS

How many cell factories does the Volkswagen Group target to open in Europe by 2030?

The Volkswagen Group targets to operate six cell factories in Europe with a total capacity of 240GWh by 2030.Who will lead PowerCo?

PowerCo will be led by Chief Executive Officer Frank Blome, Chief Operations Officer Sebastian Wolf, and Chief Financial Officer Kai Alexander Muller, among others.

During the groundbreaking ceremony, Scholz said, “Today is a good day for the automotive industry in Germany and Europe. Volkswagen is showing how the future of sustainable, climate-compatible mobility could look. Together, we are laying the foundation for shaping this future to a significant extent in Salzgitter.”

“Today, we are not only laying a foundation stone but also marking a strategic milestone,” Volkswagen AG Chief Executive Officer Herbert Diess stated. “The battery cell business is one of the cornerstones of our New Auto strategy which will make Volkswagen a leading provider of the sustainable, software-driven mobility of tomorrow. Establishing our own cell factory is a megaproject in technical and economic terms. It shows that we are bringing the leading-edge technology of the future to Germany!”

With immediate effect, the PowerCo will run international factory operations, cell technology advancement, vertical value chain integration, and factory equipment and machinery supply. Future plans call for further products including major grid-scale energy storage systems. The next cell factory after Salzgitter will be built in Valencia. In addition to Europe, PowerCo is already looking into the prospect of adding further gigafactories in North America.

PowerCo will be led by Chief Executive Officer Frank Blome, Chief Operations Officer Sebastian Wolf, and Chief Financial Officer Kai Alexander Muller, among others.

“In building our first in-house cell factory, we are consistently implementing our technology roadmap. PowerCo will become a global battery player. The company’s major strength will be vertical integration from raw materials and the cell right through to recycling. In future, we will handle all the relevant activities in-house and will gain a strategic competitive advantage in the race to take the lead in e-mobility. We have secured a top team for this great undertaking,” Volkswagen AG Board of Management responsible for Technology Member and PowerCo Supervisory Board Chairman Thomas Schmall said.

“At Salzgitter, we can see the transformation of the automotive industry more clearly than at any other location in Germany,” Lower Saxony Minister-President Stephan Weil stated. “Battery cells are soon to be produced where conventional engines are still rolling off the production line. Jobs for the future are being created here. The heart of the automotive industry will be electric in the future and it will be beating in Lower Saxony.”

The Volkswagen Group unveiled the standard factory concept for the first time at the groundbreaking event. Salzgitter will serve as a model for cell factories across Europe and establish new benchmarks for sustainability and innovation.

“What we have put to the test millions of times over with vehicle platforms such as the MQB and MEB will also lay the foundation for establishing cell production: we will be standardizing on the basis of European standards and upscaling. This way, we will combine speed and cost optimization with the highest quality levels,” Blome said.

Equipment, buildings, and infrastructure will not be the only things that will be standardized; also included are products, procedures, and IT. On this basis, factories that can be quickly modified for new product and production improvements will be built. Each facility will run entirely on renewable energy and be built to support closed-loop recycling in the future.

Additionally, Volkswagen presented the prismatic unified cell that was announced during the Power Day in 2021. Up to 80% of all Volkswagen Group models will make use of this, which enables the flexible usage of a variety of cell chemistries. From 2025 on, Salzgitter will develop unified cells for the volume segment. The plant will eventually have a 40GWh annual capacity, which will be sufficient to power around 500,000 electric vehicles. The Volkswagen Group targets to operate six cell factories in Europe with a total capacity of 240 GWh by 2030. By harnessing synergy effects, the new unified cell will lower battery costs by up to 50%. The latest batch of prototypes have shown incredibly promising performance in terms of range, charging speed, and safety — all crucial requirements for a future industrial standard.

Photos from Volkswagen Group

Also read: Volkswagen closes Europcar transaction, eyes to boost mobility services

Sell your car at the best price

Verified and genuine buyers

Verified and genuine buyers

Volkswagen Car Models

PIMS 2024

Trending & Fresh Updates

- Latest

- Popular

You might also be interested in

- News

- Featured Stories

Volkswagen Featured Cars

- Popular

Latest Volkswagen Car Videos on Zigwheels

Volkswagen Car Articles From Carmudi

- journal