Volkswagen Group ramps up Industrial Cloud integration of facilities

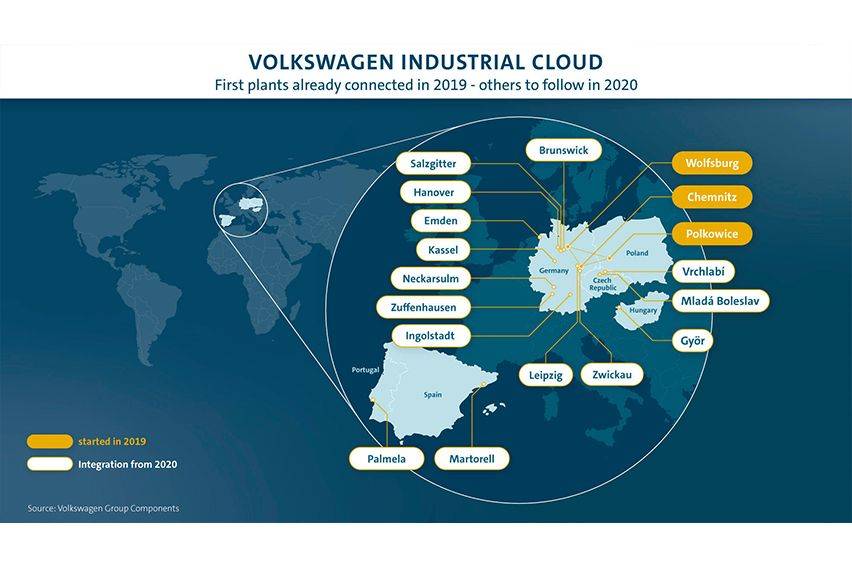

MANILA: The Volkswagen Group is moving ahead with the incorporation of its facilities into the so-called Volkswagen Industrial Cloud to increase the efficiency of its facilities and lessen production costs. In 2019, the first three plants were already connected.

According to the head of production of the Volkswagen Group, Gerd Walker, the plan for 2020 is to take the cloud to 15 plants. The work on the initiative continued steadily despite the temporary suspension of production during the COVID-19 crisis.

The head of enterprise of platform architecture of the Volkswagen Group, Roy Sauer, said that the company is continuously progressing and substantially increasing the pace.

Walker also added that from 2016 to 2025, the auto company expects to improve the efficiency of its facilities by 30% and that the Industrial Cloud is a crucial instrument for achieving this goal. Overall, the Volkswagen Group anticipates cost savings adding up to several billion euros when information for all 124 plants can be analyzed systematically. The Industrial Cloud is based on Amazon Web Service (AWS), and Siemens is considered an integration partner.

In 2019, the Volkswagen Group began initially with Poland, Wolfsburg, and Chemnitz facilities of the Volkswagen Passenger Cars brand, in line with its planning.

Walker also pointed out that the Volkswagen Group is now bringing the Industrial Cloud and forcing the pace to numerous plants. This 2020, a maximum of 15 further plants from the Porsche and Components, Volkswagen Commercial Vehicles, Volkswagen Passenger Cars, Skoda, Seat, and Audi brands will be connected. These include the facilities in the Czech Republic, Hungary, Portugal, Spain, and Germany.

According to the vice president of AWS IoT, Amazon Web Services (AWS), Dirk Didascalou, the functionality that they collectively built on top of AWS offers a consistent and cost-efficient way of gathering and organizing facility data into the Industrial Cloud. It also speeds up the flow of cases that enhance the efficiency of the logistics and production processes of Volkswagen.

For the first phase, the Volkswagen Group identified 15 various applications that are now being made accessible for all facilities as standardized apps. The primary goals include the decrease of reworking on vehicles and predictive machine maintenance through artificial intelligence (AI).

Data from numerous facility items and machines will be captured via sensors in terms of the “brownfield” method. These will be processed through standardized Cloud apps. Any system, piece of equipment, or machine can be manually connected. As for older systems, sensors are needed for the installation of sensors.

During the final phase of development, the total volume of data for daily processing will be matched to the amount of information from a small community in Germany.

Sauer explained that they have the expertise within the Volkswagen Group to extract efficiency potentials from the data and that they are substantially enhancing their skills. At present, 220 specialists within the Volkswagen Group are working closely on the project, and this number will increase to around 500 by the later part of 2020.

Volkswagen currently develops the applications and solutions for it to be accessible to other companies within an open environment. Development work on such applications will proceed along with other companies.

There is no emphasis on the automotive industry in this context. Discussions with several collaborators from numerous industries have entered a very advanced level. The combined development and use provide significant benefits to those involved since they do not need to develop the services and software by themselves. They can also benefit from collaborations within the system.

Photo from Volkswagen

Sell your car at the best price

Verified and genuine buyers

Verified and genuine buyers

Volkswagen Car Models

PIMS 2024

- Latest

- Popular

You might also be interested in

- News

- Featured Stories

- Popular

Latest Volkswagen Car Videos on Zigwheels

Volkswagen Car Articles From Carmudi

- journal